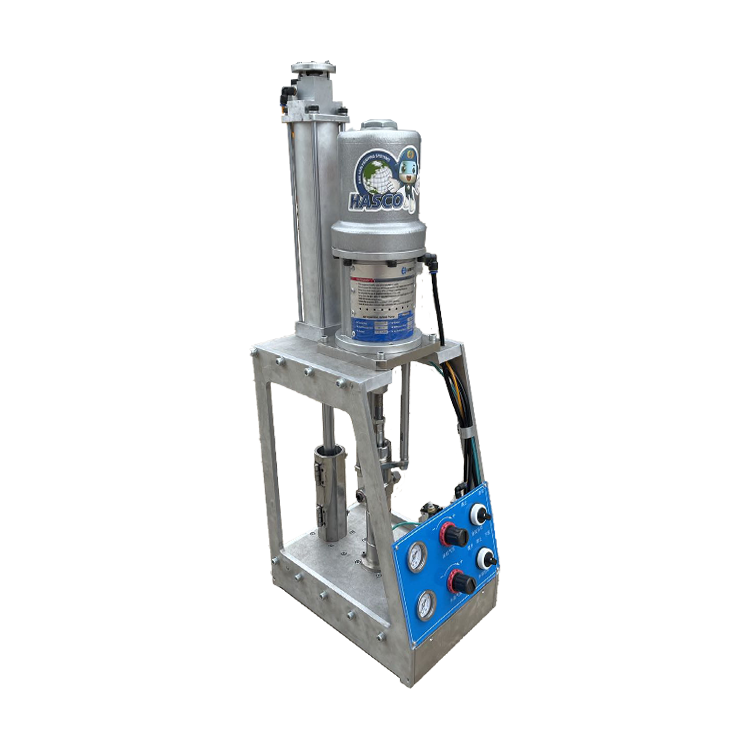

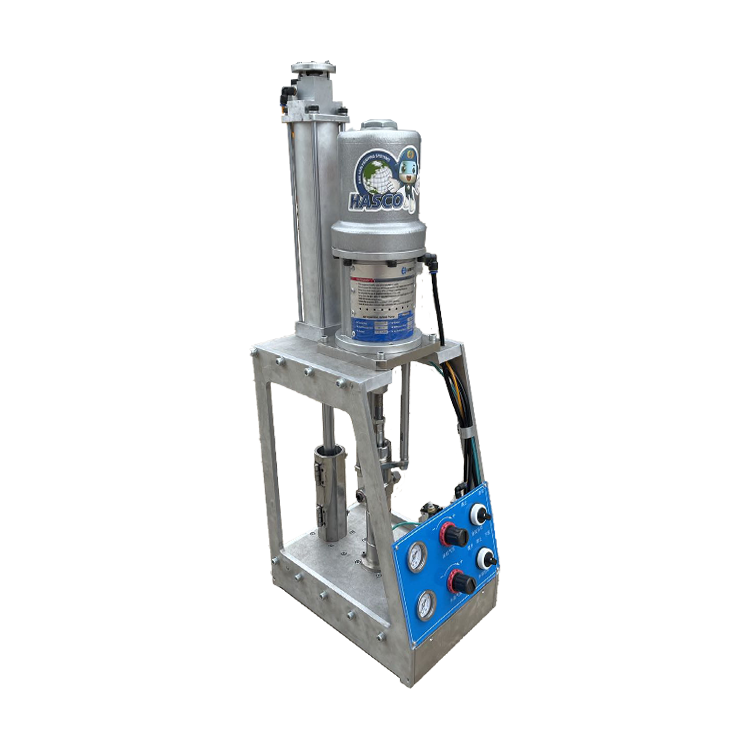

点胶机操作流程以及维护保养事项

点胶机主要用于产品工艺中的胶水、油漆以及其他液体精确点、注、涂、点滴到每个产品精确位置,可以用来实现打点、画线、圆型或弧型。下面来讲讲点胶机操作流程以及维护保养事项。

Glue dispenser is mainly used to accurately spot, inject, apply and drip glue, paint and other liquids in the product process to the precise position of each product, and can be used to achieve dot, line, circle or arc. Let's talk about the operation process and maintenance of the dispensing machine.

点胶机操作流程:

Operation process of dispensing machine:

一、装置需要点胶产品的固定架,打开气压、机器电源,在胶管内灌入需要运用的胶水,固定好胶管运用高度。

1、 The device requires a fixed frame for dispensing products. Turn on the air pressure and machine power supply, fill the rubber hose with the glue that needs to be used, and fix the application height of the rubber hose.

二、编程:依据产品点胶图形,编制程序。程序编好后设置点胶速度、Z轴进步高度相对值、点胶时间参数。

2、 Programming: compile the program according to the dispensing graphics of the product. After programming, set the dispensing speed, the relative value of z-axis progressive height, and the dispensing time parameters.

三、参考点设置:进入Setup﹥选择参考点运用,按下ENTER此参考点将被记载,并在固定架上做上符号。如针头有变动时则针头将不在参考点上,通过调整X、Y、Z轴批改参考点,调整完成后按下Home从头回归原点,即可设完成。

3、 Reference point setting: enter setup > select reference point application, press enter, this reference point will be recorded, and a symbol will be made on the fixed frame. If the needle changes, the needle will not be on the reference point. Correct the reference point by adjusting the X, y and Z axes. After the adjustment is completed, press home to return to the original point from the beginning, and the setting can be completed.

四、气压设定:依据胶水粘稠度设置对应运用气压。

4、 Air pressure setting: set the corresponding application air pressure according to the viscosity of the glue.

五、程序、设置完成后,按下机器上的RUN/TEACH开关,放置产品按下Start键开始点胶,每换产一只产品,都需按下Start键。

5、 After the program and setting are completed, press the run/teach switch on the machine, place the product and press the start key to start dispensing. Press the start key every time you change a product.

点胶机维护保养:

Maintenance of dispensing machine:

1、

济南双组份打胶机厂家提醒,更换胶种,需清洗管路。此时先关闭进料阀,打开排料阀,将胶桶剩余胶料排出后,关闭排料阀打开进料阀将清洗溶剂倒入储胶桶内,机体,按平时操作方式将溶剂压出冲洗。

1. The manufacturer of Jinan two-component glue applicator reminds that the pipeline needs to be cleaned before changing the glue type. At this time, first close the feeding valve, open the discharging valve, discharge the remaining rubber in the rubber barrel, close the discharging valve, open the feeding valve, pour the cleaning solvent into the rubber barrel, activate the machine body, and press the solvent out for washing according to the normal operation mode.

2、气压进气不正常及发现有水气,请将调压过滤器内之水气排除或检查气压源有无异样即可。点胶机在胶水大量使用前,请先小量试用,掌握产品的使用技巧,以免差错,当测试没问题时,再用双液滴胶机或双液灌胶机进行大批量的生产;抽真空系统对胶水进行抽真空除泡处理,以排除搅拌过程中产生的气泡,或静置10-20分钟再使用,以使混合时产生的气泡及时排除,混合在一起的胶量越多。

2. If the air pressure intake is abnormal and water vapor is found, please remove the water vapor in the pressure regulating filter or check whether the air pressure source is abnormal. Before the glue dispenser is used in large quantities, please try it in small quantities to master the use skills of the product to avoid mistakes. When the test is OK, then use the double liquid glue dropping machine or double liquid glue filling machine for mass production; The vacuum system vacuumizes and defoaming the glue to eliminate the bubbles generated during mixing, or it can be used after standing for 10-20 minutes, so that the bubbles generated during mixing can be eliminated in time, and the more glue mixed together.

3、机台部分请定期擦拭干净,以增加使用寿命。混合在一起的胶量越多,其反应就越快,固化速度也会越快,所以要根据实际生产情况进行合理配胶,否则造成胶水的浪费。排除意外,提高生产效率。如今液体控制技术和点胶设备广泛地应用到现代工业中的各种生产领域。

3. Please wipe the machine regularly to increase its service life. The more glue is mixed together, the faster the reaction will be and the faster the curing speed will be. Therefore, it is necessary to mix the glue reasonably according to the actual production situation, otherwise it will cause a waste of glue. Eliminate accidents and improve production efficiency. Nowadays, liquid control technology and dispensing equipment are widely used in various production fields in modern industry.

In addition, the machine should be unplugged when it is out of service for a long time, which can not only prolong the service life of the machine, but also save a lot of electricity. Come to the website for more relevant content http://www.jntiannuo.com Consult and understand.

上一篇:打胶机在打胶中发生断胶解决小妙招

下一篇:双组份打胶机在操作时的注意事项