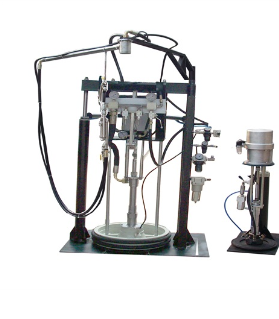

自动灌胶机的操作守则!

一、自动灌胶机开机流程

I. Start-up process of automatic glue filling machine

1、检查灌胶区,如有杂物、工具等,必需清算洁净;

1. Check the glue-filling area. If there are any sundries and tools, it must be cleaned up.

2、检查紧缩空气能否在正常范围,电源能否满足请求;

2. Check whether the compressed air can be in the normal range and whether the power supply can meet the requirements.

3、钥匙开关右转,给机器通电;

3. Turn the key switch right and power the machine.

4、装混合管前测试双液阀动作能否正常,出胶量能否精确,灌胶的产品或胶水与上一次的不同,要停止配比调试;

4. To test whether the action of double liquid valves is normal, whether the quantity of glue is accurate, and whether the product or glue of glue filling is different from that of the last time, it is necessary to stop the ratio debugging.

5、装混合管后测试动态搅拌能否正常,同时吐出AB胶,确认混合管充溢且没有气泡;

5. Test whether the dynamic stirring is normal after installing the mixing tube, and vomit AB glue at the same time to confirm that the mixing tube is full and there is no bubble.

6、摆放产品,编辑程序或起点位置,在关胶状态,考证三轴的运转途径能否满足请求;

6. Place the product, edit the program or the starting point, check the running way of the three axes to satisfy the request.

7、按主画面的“关胶”键,使其显现“开胶”,按绿色启动按钮,停止消费, 需求暂停,按绿色按钮,紧急状况,按急停按钮。

7. Press the "off glue" button on the main screen to make it appear "open glue", press the green start button, stop consumption, stop demand, press the green button, press the emergency button, press the emergency stop button.

二、关机流程

II. Shutdown process

1、假如开启了循环功用,一个产品灌胶时,关闭循环功用;

1. If the circulation function is opened, the circulation function is closed when a product is glued.

2、有自动清洗功用的,运转自动清洗。无自动清洗功用的,拆下混合管,同时出AB胶3-5秒,用碎布擦拭洁净双液阀阀头;3、关闭电源,清算机台,清洗混合管等。

2. With the function of automatic cleaning, it can be operated and cleaned automatically. If there is no automatic cleaning function, remove the mixing pipe and give out AB glue for 3-5 seconds at the same time, wipe clean the valve head of the double liquid valve with rag; 3. Close the power supply, clean the mixing pipe, etc.

三、短时停机

3. Short-term shutdown

1、假如开启了循环功用,一个产品灌胶时,关闭循环功用;

1. If the circulation function is opened, the circulation function is closed when a product is glued.

2、开启自动排胶功用,留意自动排胶时间,要在胶水变稠前排胶。

2. Open the function of automatic dispensing, pay attention to the time of automatic dispensing, and dispel glue before the glue thickens.

四、真空灌胶机灌胶过程中留意事项

IV. Notices in the Process of Vacuum Filling Machine Filling

1、在套上“混合管”之前,进入“配胶画面”,检测AB胶的出胶能否顺畅,出胶量能否精确;

1. Before putting on the "mixing pipe", enter the "glue matching screen" to check whether the glue of AB glue is smooth and the glue quantity is accurate.

2、检查“混合管、螺旋叶片、针头、针嘴”能否洁净,有无异物梗塞;

2. Check the cleanliness of "mixing tube, spiral blade, needle and needle nozzle" and whether there is foreign body infarction.

3、在产品灌胶前应把5秒AB混合胶的出胶量记载好,在产品灌胶过程中约每两小时检测一次AB胶重量能否与记载的值分歧,假如变动过大,要马上停机检查,否则胶水可能不干;

3. Record the amount of 5 seconds AB mixed glue before product filling. Check whether the weight of AB glue differs from the recorded value every two hours during product filling. If the change is too big, stop the machine immediately to check. Otherwise, the glue may not dry.

4、亲密留意AB胶桶的胶量,AB胶桶中在没有胶水状况下空动行,会对供胶局部有所损伤;

4. Pay close attention to the amount of glue in AB bucket. If AB bucket moves without glue, it will damage the glue supply part.

5、放置产品到夹具上时,要放在相同的位置上;

5. Place the product on the fixture in the same position.

6、依据胶水固化时间,暂时灌胶十五分钟以上,恢复灌胶时应检测 AB混合胶吐出重量;

6. According to the curing time of glue, temporary glue filling should be more than 15 minutes. When restoring glue filling, the vomiting weight of AB mixed glue should be detected.

7、依据胶水固化时间,暂停灌胶约三非常钟以上,要取下混合管停止清洗。

7. According to the curing time of glue, the filling time should be suspended for more than 30 minutes, and the mixing pipe should be removed to stop cleaning.

上一篇:中空玻璃打胶机生产效率怎么样?

下一篇:自动补胶电气的维护程序!