打胶过程中出现花胶现象怎么办?

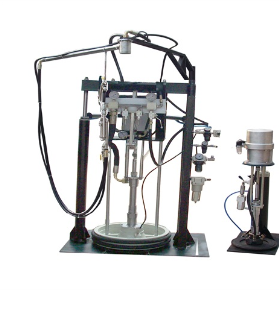

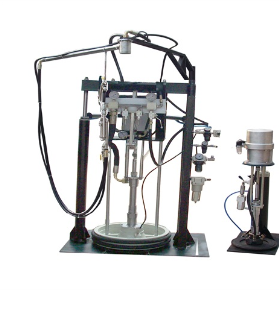

运用硅酮构造密封胶时,在打胶施工现场,经常会遇到这些问题:打胶机出胶速度慢,表干拉断时间太快或太慢、打胶过程中呈现“花胶”、 结皮或硫化现象等。

When using silicone to construct sealant, these problems often occur in the construction site of gluing: the gluing speed of gluing machine is slow, the breaking time of surface drying is too fast or too slow, the phenomenon of "floral glue", "crust" or vulcanization appears in the gluing process.

当发现这些问题反响会想到胶的质量问题,从而可能由于投诉以要改换的问题而搅扰。

When these problems are found, the first reaction will be the quality of the glue, which may be disturbed by complaints and even the problem of brand change.

其实招致这些现象呈现的状况还与其他要素有关,详细的判别、扫除可能要素并实验比照能够快速的处理以上问题,到达事半功倍的效果。

In fact, the situation that causes these phenomena is also related to other elements. Detailed identification, elimination of possible elements and experimental comparison can quickly deal with the above problems and achieve twice the result with half the effort.

1. 打胶机出胶速度慢

1. The gluing speed of the gluing machine is slow.

产品在初次运用时,打胶机打胶过程中呈现出胶速渡过慢的现象,可能缘由有三个:⑴A组分活动性差⑵压盘过大⑶气源压力不够。

When the product is used for the first time, the glue speed of the glue beater passes too slowly during the gluing process, which may be due to three reasons: poor activity of component A, too large pressure plate and insufficient gas source pressure.

针对缘由⑴或缘由⑶,我们能够经过调整胶枪压力来处理;针对缘由⑵,订购大口径桶能够使问题得到处理。若出胶速度慢呈现在正常运用过程中,则可能是混合芯和过滤网被梗塞,一旦发现,就需求及时清算设备。

For reason (1) or reason (3), we can deal with the problem by adjusting the pressure of the rubber gun; for reason (2), ordering large caliber barrels can solve the problem. If the speed of glue production is slow in the normal operation process, it may be that the mixing core and filter are obstructed, once found, the need for timely liquidation equipment.

2. 打胶过程中呈现“花胶”

2. Presenting "floral glue" in the process of gluing

花胶是由于A/B组分胶体混合不平均而产生的,表现为固化慢或部分有白色条纹。

Flower gum is produced by the uneven mixing of colloids of A/B component, which is characterized by slow curing or partly white streaks.

主要缘由有:⑴打胶机B组分管道梗塞⑵静态混合器长时间未清洗⑶比例尺松动,出胶速度不平均⑷换厂家或牌号未调整设备工艺参数⑸改换后的产品挤出性不好,设备未顺应⑹混用不同厂家不同牌号的A、B组分。

The main reasons are: (1) Pipeline infarction of component B of glue beater; (2) static mixer has not been cleaned for a long time; (3) scale loosening; (4) the speed of glue production is uneven; (4) the process parameters of the equipment have not been adjusted by the manufacturer or the brand; (3) the extrusion performance of the product after the change is not good, and the equipment does not conform to (3) mixing different brands of component A and B from different manufacturers.

针对缘由⑴、⑵,能够经过清洗设备来处理;针对缘由⑶,则需求检查比例控制器,并停止恰当的调整;针对缘由⑷、⑸,在保证参数正确的前提下,运用1-2天后设备会逐步顺应。

For reasons_and_, it can be processed by cleaning equipment; for reasons_, it is necessary to check the proportional controller and stop the appropriate adjustment; for reasons_and_, the equipment will gradually adapt after 1-2 days of operation on the premise of ensuring the correct parameters.

3. 打胶过程中胶体呈现结皮或硫化现象

3. Colloids crust or vulcanize during beating

当双组份胶在混合过程中就发作部分固化时,胶枪打出来的胶就会呈现结皮或硫化现象。呈现这一现象的缘由主要有三种:

When the two-component glue is partially cured during mixing, the glue produced by rubber gun will appear crust or vulcanization. There are three main reasons for this phenomenon:

⑴胶体颜色较黑,固化快时,可能是由于B组分比例过高,过多的催化剂促使固化速度加快。此时,需求恰当降低B组分的比例,将结皮或硫化胶冲洗洁净后施工;

(1) When the colloid is black and solidified quickly, it may be due to the high proportion of B component, and the excessive catalyst promotes the speed of solidification. At this time, it is necessary to reduce the proportion of B component appropriately and rinse the crust or vulcanizate before construction.

⑵若打胶过程中伴有出胶慢的现象时,可能是混合芯长时间未清洗或清洗不彻底,胶体结皮梗塞管道。因而,定期清洗静态混合器是很有必要的。

(2) If the gelling process is accompanied by slow gelling, it may be that the mixing core has not been cleaned for a long time or is not thoroughly cleaned, and the gel crust obstructs the pipeline. Therefore, it is necessary to clean the static mixer regularly.

⑶当固化和出胶速度均无异常,而打出的胶仍有结皮或硫化现象时,则可能是设备停机时间较长,胶枪未清洗或洗枪不够彻底,需求将结皮或硫化胶冲洗洁净后后施工。

(3) When there is no abnormal curing and tapping speed, and there is still crust or vulcanization in the tapped rubber, it may be that the equipment has been shut down for a long time, the rubber gun has not been cleaned or the gun has not been cleaned thoroughly enough, so it is necessary to rinse the crust or vulcanizate before construction.

4、胶内夹有气泡

4. Bubbles in glue

普通而言,胶体自身是没有气泡的,胶体夹有的气泡极可能是运输或施工过程中混入了空气,如:⑴改换胶桶时排气未排洁净;⑵组分在上机后压盘未压下去,招致排泡不彻底。

Generally speaking, the colloid itself does not have bubbles, and the bubbles in the colloid are likely to be mixed with air during transportation or construction, such as: (1) the exhaust is not cleaned when changing the rubber drum; (2) the components are not pressed down on the pressure plate after the machine, resulting in incomplete defoaming.

因而,在运用前排泡要彻底,运用过程中应正确操作打胶机,保证密封从而阻止空气进入。若疑心产品本身就带有气泡,能够经过蝴蝶实验来停止判别。

Therefore, in the use of front row foam to be thorough, the use of the process should be correctly operated glue beater, to ensure that the seal to prevent air from entering. If you suspect that the product itself has bubbles, you can stop discriminating by butterfly experiments.

上一篇:中空玻璃打胶机的耗电量高不高?

下一篇:打胶机连续运转并报警的原因!