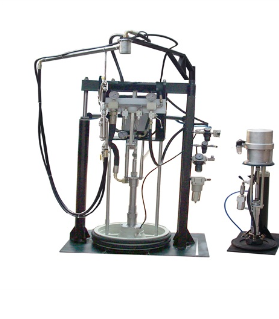

自动打胶机胶体粘度对产品性能的影响!

自动配胶机胶体粘度对产品性能的影响

Effect of Colloidal Viscosity of Automatic Rubber Mixing Machine on Product Performance

在自动配胶机的滚压过程中,胶体与液体在相邻的液层之间存在着相应的活动。这两层之间的碰撞阻力称为胶体粘度。

In the rolling process of automatic rubber mixer, there are corresponding activities between colloid and liquid in the adjacent liquid layer. The collision resistance between these two layers is called colloidal viscosity.

自动点胶机胶体粘度对产品的影响:

The influence of colloid viscosity of automatic dispenser on the product:

胶体粘度对包装精度、包装粘结性和包装的整体质量都关重要,因此胶体粘度是自动点胶机在包装过程中越来越重要的参数。

Colloidal viscosity is very important to packaging accuracy, packaging cohesion and overall packaging quality. Therefore, colloidal viscosity is an increasingly important parameter in the packaging process of automatic dispensing machine.

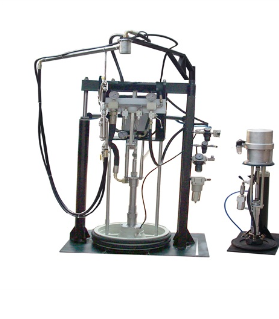

自动配料机的使用包装在包装的过程中,发现每个凝胶粘度的有用的步骤来实现控制,一直是流体控制设置制造商和所有的行业努力重要课题,下一个自动配药机制造商介绍胶体粘度异常的解决方案。

The use and packaging of automatic batching machine in the packaging process, we found that each gel viscosity useful steps to achieve control, has been an important issue for manufacturers of fluid control settings and all industries, the next automatic dispensing machine manufacturers to introduce colloidal viscosity anomaly solutions.

胶体粘度常用的步骤之一是装配加热器,这是所有方法中常见和快的方法之一。

One of the most common steps for colloidal viscosity is to assemble heaters, which is one of the most common and fastest methods of all.

在某些特定的包装条件和包装条件下,需要增加的情况下,胶体温度要与包装工艺相匹配。在一定的大范围内,胶体的高温引起脉冲降低,从而引起温度转变,从而保证了流体的稠度。

In some specific packaging conditions and packaging conditions, the colloid temperature should be matched with the packaging process when it needs to be increased. In a certain range, the high temperature of the colloid causes the pulse to decrease, which leads to the temperature transition, thus ensuring the consistency of the fluid.

其他需求与胶体粘度的包装、胶体粘度和中介的操作也是一个大级别减少和修改自动配药机在封装过程中经常出现的拉丝后的频率,液体自动配料机,胶机胶线的过程中封装、比特率和粘度范围为所有包装产品质量影响从长远来看,胶体的控制过程,技术有待进一步加强。

Other requirements and colloid viscosity packaging, colloid viscosity and intermediary operation are also a large-scale reduction and modification of automatic dispensing machine in the packaging process often occurs after wire drawing frequency, liquid automatic dispensing machine, glue machine in the process of packaging, bit rate and viscosity range of all packaging product quality impact in the long run, colloid control process, technology needs to be further strengthened. 。

上一篇:自动灌胶机封装过程中液料的处理!

下一篇:点胶机胶阀的运用要注意哪些问题?