双液点胶机有哪些类型呢?

双液点胶机有哪些类型呢?它们各自有什么优缺点呢?下面为您做一下具体的介绍:

What are the types of double liquid dispenser? What are their advantages and disadvantages? Here is a detailed introduction for you:

一,简易式双液点胶机

1. Simple double-liquid dispensing machine

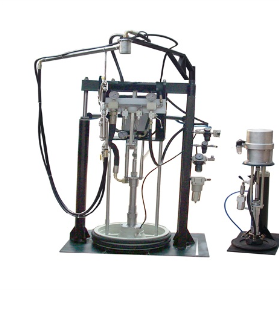

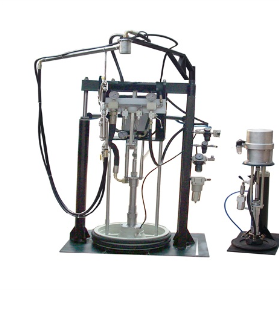

由两个压力桶和一个点胶控制器组成。将AB胶分别倒入到压力桶中,通过气压将胶水压出来,通过点胶控制器来调节气压的压力和出胶时间,进而来控制出胶量。此类型双液点胶机主要用于1:1的胶水。对于高于1:1的胶水,如4:1,5:1,10:1,10:3这样的胶水则不适用。因为这种简易的双液点胶机两边压力是一样的,另外气压也是不稳定的,有波动的,而比例相差较大的胶水,配比一定要精确,否则打出胶水是不干的。气压的波动会使胶水出来的忽多忽少,其比例就很难保证精确,一比一的胶水还好,无论A胶还是B胶哪一个多一点,或者少一点都会干,而多比例的胶水则非常严格,一定要精确。另外当前点胶控制器也有局限,从控制器给到两个桶的压力是一样的,对于多比例的胶水,一边的压力要是另一边压力的倍数,但目前控制器做不到这一点。也许你会说增加一个储气罐,保持气压的稳定,解决气压波动,但是控制器这一块还是个瓶劲,还是没法解决多比例的胶水。另外如果胶水比较稠,气压的压力毕竟有限,就会出现打胶比较慢,效率不高,而一比一的胶水大部份都会比较粘稠,所以简易式双液点胶机目前主要以1:1胶水为主,也很便宜,主要适用于对效率要求不是很高的企业。简易式双液点胶机如下图所示:简易双液点胶机

It consists of two pressure barrels and a dispensing controller. The AB glue is poured into the pressure barrel separately, and the glue is pressed out by the air pressure. The pressure of the air pressure and the time of glue release are regulated by the dispensing controller to control the glue output. This type of double-liquid dispenser is mainly used for 1:1 glue. For glue above 1:1, such as 4:1, 5:1, 10:1, 10:3 glue is not applicable. Because the pressure on both sides of this simple double-liquid dispenser is the same, and the pressure is also unstable and fluctuating, and the proportion of glue with large difference must be accurate, otherwise the glue is not dry. The fluctuation of air pressure will make the glue come out more or less, and its proportion is difficult to guarantee accuracy. One-to-one glue is better. No matter which one of A glue or B glue is more or less, it will dry, while the proportion of glue is very strict and must be accurate. In addition, the current dispensing controller also has limitations. The pressure from the controller to the two barrels is the same. For a large proportion of glue, the pressure on one side is a multiple of the pressure on the other side, but the current controller can not do this. Maybe you would say adding an air storage tank to keep the pressure stable and to solve the fluctuation of the pressure, but the controller is still a bottle power and still can't solve the problem of a large proportion of glue. In addition, if the glue is thicker and the pressure of air pressure is limited after all, there will be slow gluing and inefficient glue, and most of the glue will be thicker than one, so the simple double-liquid dispenser is mainly 1:1 glue at present, and the price is also cheap. It is mainly applicable to enterprises that do not require high efficiency. Simple double-liquid dispensing machine as shown in the following figure: Simple double-liquid dispensing machine

二,台式双液点胶机

2. Desktop double-liquid dispensing machine

台式双液点胶机的原理和简易式双液点胶机是一样的,就增加了一个三轴机械手,实现自动点胶功能,将多个产品放在夹具上,一次性打完。而简易式双液点胶机每次只能打一个,这样效率就提升了,但局限还是有的,只适用于一比一的胶水。台式双液点胶机如下图所示:台式双液点胶机

The principle of desktop double-liquid dispensing machine is the same as that of simple double-liquid dispensing machine. A three-axis manipulator is added to realize the automatic dispensing function. Many products are put on the fixture and finished at one time. The simple double-liquid dispensing machine can only play one at a time, which improves the efficiency, but there are still some limitations, only for one-to-one glue. The table double-liquid dispensing machine is shown in the following figure: the table double-liquid dispensing machine

三,半自动双液点胶机

3. Semi-automatic double-liquid dispensing machine

半自动双液点胶机通过计量泵来计量,一个A泵,一个B泵。泵通过电机来驱动,电机带动泵转,每转一圈其出胶体积是恒定的,不受气压控制,所以泵的出胶量是非常稳定的,误差是非常小的。泵转的越快,其出胶也就越快,出胶量也就越大,对于多比例的胶水,在触摸屏中调节泵的转速就可以了。另外泵的压力相对于气压来讲,要大的多,所以出胶也会很快,点胶的效率较气压式的要快很多。计量泵的灌胶机从功能来讲带有自动清洗功能,维护很简便,气压式的灌胶机没有这个功能,点胶作业后,要手动的去拆下来清洗。计量泵点胶机料桶带有液位感应功能,缺料会自动报警提示加胶;还带有搅拌功能防止胶水沉淀,也可选配胶水抽真空功能,对胶水脱泡,减少点胶气泡发生;也可以配置加热功能,防止天气变冷胶水变稠流不动。半自动双液点胶机标配通过脚踏开关来控制出胶,针对比较小巧的产品,半自动双液点胶机可外接手动枪阀,通过手按开关来控制出胶,让操作更灵活。半自动双液点胶机同气压式相比,功能比较强大,适用于多比例胶水,点胶效果更好,但方面要比气压式的贵很多。

Semi-automatic double-liquid dispensing machine is metered by metering pump, one A pump and one B pump. Pump is driven by motor, which drives the pump to rotate. The gel volume is constant in every turn and is not controlled by air pressure, so the gel volume of pump is very stable and the error is very small. The faster the pump rotates, the faster the glue is produced, and the larger the glue output. For a large proportion of glue, it is OK to adjust the speed of the pump in the touch screen. In addition, the pressure of the pump is much larger than that of the air pressure, so the glue will be produced quickly, and the dispensing efficiency is much faster than that of the air pressure type. The glue filling machine of metering pump has the function of automatic cleaning, which is easy to maintain. The pneumatic glue filling machine does not have this function. After dispensing, it should be removed and cleaned manually. The barrel of metering pump dispensing machine has the function of liquid level induction, which can automatically alarm and prompt glue feeding for material shortage; it also has the function of stirring to prevent glue precipitation; it can also choose the function of glue vacuum pumping to defoam glue and reduce the occurrence of dispensing bubbles; it can also be equipped with heating function to prevent the glue from becoming thick and immobile when the weather becomes cold. Semi-automatic double-liquid dispensing machine standard through the pedal switch to control the glue out, for smaller products, semi-automatic double-liquid dispensing machine can be connected with manual gun valve, through the manual switch to control the glue out, so that the operation is more flexible. The semi-automatic double-liquid dispensing machine is more powerful than the pneumatic dispensing machine. It is suitable for multi-proportion glue dispensing. The dispensing effect is better, but the price is much more expensive than the pneumatic dispensing machine.

四,三轴自动双液点胶机

Fourth, three-axis automatic double-liquid dispensing machine

三轴自动双液点胶机在原理上跟半自动双液点胶机是一样的,其不同点就是多了一个三轴机械手,实现产品批量点胶,减少人工拿放工序,效率要高一些。三轴自动双液点胶机对产品的标准性要求较高,就是产品每个要一样,不能变型,三轴机械手点胶是按照设定的轨迹来走,如果要点胶的孔位不一致,就有可能出现胶水点到外面来了。双液自动点胶机需要治具来定位,而半自动点胶机则不需要。对于多样化的产品,产品一致性比较差的产品,还有体积比较大的产品,半自动双液点胶机则更适合。三轴双液自动点胶机如下图所示:自动双液点胶机

The principle of three-axis automatic double-liquid dispensing machine is the same as that of semi-automatic double-liquid dispensing machine. The difference is that there is an additional three-axis manipulator to realize batch dispensing of products, reduce manual handling and release process, and the efficiency is higher. Three-axis automatic double-liquid dispensing machine requires higher standard of products, that is, each product should be the same, can not be modified, three-axis manipulator dispensing is in accordance with the set trajectory, if the hole position of the key glue is not consistent, it may appear glue point to the outside. Double-liquid automatic dispensing machine needs fixtures to locate, while semi-automatic dispensing machine does not. For a variety of products, products with poor consistency, and products with larger volume, semi-automatic double-liquid dispenser is more suitable. The three-axis double-liquid automatic dispensing machine is shown in the following figure: automatic double-liquid dispensing machine

五,双液点胶机流水线

5. Dual-liquid dispenser assembly line

双液点胶机流水线,由接驱台,点胶机,真空机,固化炉,打标机,回转线等组成,其优点就是减少人工干扰,出来就是成品,产品品质的可靠性更高,效率更高,节省了大量人工,成本可以降低很多,但缺点就是前期投入比较大。双液点胶机流水线如下图所示:

Dual-liquid dispensing machine assembly line is composed of receiving and dispensing platform, dispensing machine, vacuum machine, curing furnace, marking machine, revolving line, etc. Its advantages are to reduce manual interference. It comes out as a finished product. The product has higher reliability, higher efficiency, saves a lot of labor and reduces costs, but the disadvantage is that the earlier investment is relatively large. The assembly line of the double-liquid dispenser is shown as follows:

综上即为双液点胶机的几种类型介绍,每一种都有自己有优势,可以根据自己当前的实际情况来选取。适合自己的才是好的!

To sum up, it is the introduction of several types of double-liquid dispenser, each of which has its own advantages and can be selected according to its current actual situation. What suits you is the best!

上一篇:点胶机的胶量忽大忽小是什么原因?

下一篇:打胶机怎么选择合适的点胶针头?