怎么清洗灌胶机?

,假如您灌的产品一直是同一种胶水,中间不会换胶水,中间因为产品没有供应上,里边的胶水还没有用完,需要放置几天,等产品到位后再灌,这些环境下,清洗很是的简单,假如有主动清洗功用,将清洗阀门打开,在操作系统中按一下主动清洗,机械会主动完结清洗工作;假如没有主动清洗功用,你只需要把双液主动灌胶机上面的动态搀杂管拆下来,放到酒精,或许清洗剂中清洗一下即可。有些客户会问,那其它场所不清洗会不会堵呢?这个是不会的,因为双液主动灌胶机,A胶,B胶是分隔的,AB胶只有触摸后才会固化,双液主动灌胶机,胶水从A料筒,B料筒出来后,其触摸的部位是在搀杂管处,然后经由进程电机高速扭转带动搀杂管中的叶轮对AB胶进行切开与搀杂,所以触摸的部位也就只在搀杂管处,其它场所没有触摸,一切胶水不会固化堵住管道的,并且双液主动灌胶秘密封性很是的好,具有必定的保压功用,所以就是你中间不灌胶,机械放置在那儿那里,也是不会与空气触摸的,不会发作化学反映,放几天再用,一般环境下也是没有问题的。

First of all, if the product you pour is always the same kind of glue, the glue will not be replaced in the middle, because the product is not supplied, the glue inside is not used up, it needs to be placed for several days, and then poured after the product is in place. Under these circumstances, cleaning is very simple. If there is an active cleaning function, open the cleaning valve, press the active cleaning in the operating system, the machine will master. If there is no active cleaning function, you only need to remove the dynamic mixing pipe on the double liquid active glue filling machine and put it into alcohol, or clean it in the detergent. Some customers will ask if the other places will be blocked by unclean washing. This is not true, because the two-liquid active glue filling machine, A glue and B glue are separated. AB glue solidifies only after touching. The two-liquid active glue filling machine, when glue comes out from A barrel and B barrel, touches the part of the mixing pipe, and then drives the impeller in the mixing pipe by high-speed twisting of the process motor to inject AB glue into the mixing pipe. The line cuts and adulterates, so the touching part is only in the mixing pipe, other places do not touch, all glue will not solidify and block the pipe, and the double liquid active glue filling secret sealing is very good, with a certain pressure-keeping function, so that you do not glue in the middle, machinery placed there, will not touch with the air, will not have a chemical reaction, put a few. It's no problem to reuse it in the ordinary environment.

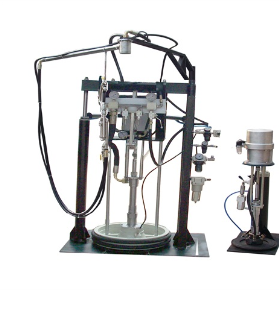

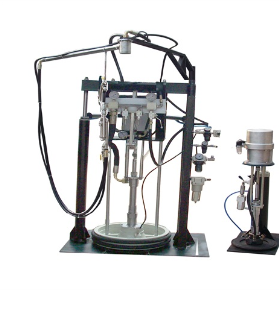

主动灌胶机

Active glue filling machine

其次,假如你要换胶水,或许机械里边胶水没有用完,下一批产品要等上半个月以上时间才用,那就要全部清洗了,因为不合的胶水搀杂在一起会发作一系列问题,如胶水中毒等。假如带有一键清先功用,那操作就斗劲简单,按一下清洗键,机械主动完结。假如双液主动灌胶机没有一键清洗功用,则清洗的时分,先将没用完的胶水排完,然后将有机溶剂,如天那水、工业酒精,放到机械里边;然后将这些有机溶剂和胶水一起压出来,再用气枪吹开即可。用此类型的机械,清洗是十分的,否则的话,长期不必,胶水固化在胶阀中,或许是料桶中就很麻烦,或许有些配件就要改换了。所以每次用完后,必定要记得清洗。

Secondly, if you want to change the glue, maybe the glue inside the machine is not used up, and the next batch of products need to wait more than half a month to use, then all of them should be cleaned, because incompatible glue mixed together will cause a series of problems, such as glue poisoning. If there is a key clearing function, then the operation is simple, press the cleaning key, and the machine will finish on its own initiative. If the two-liquid active glue filling machine has no one-button cleaning function, the cleaning time is to drain the unused glue, then put organic solvents, such as Tiannashui and industrial alcohol, into the machine; then press these organic solvents and glue together, and then blow them off with an air gun. With this type of machinery, cleaning is very, otherwise, long-term unnecessary, glue solidified in the rubber valve, perhaps in the barrel is very troublesome, perhaps some accessories will be changed. So every time you use it, you must remember to clean it.

灌胶机在清洗时常用的清洗剂有哪些:工业酒精,天那水,丙酮或二氯甲烷,一般环境下工业酒精斗劲廉价,对于有的胶水假如酒精不好清洗的话,可以用丙酮去清洗,丙酮的清洗了局很不错,就是本钱稍微高一点。

What are the commonly used cleaning agents for glue pouring machine: industrial alcohol, Tiannashui, acetone or dichloromethane, industrial alcohol is cheap in general environment. For some glue, if alcohol is not easy to clean, acetone can be used to clean, acetone cleaning board is very good, that is, the cost is slightly higher.

在对主动灌胶机清洗时:因为上除清洗剂都是一些化学溶剂,对皮肤会有必定的刺激性,并且有必定的气味,在清洗时带上防海员套,并连结车间的通风!清洗剂易辉发,易燃易爆,在利用时千万不要抽烟等!

When cleaning the active glue pouring machine: because the cleaning agent is some chemical solvent, it will have certain irritation to the skin, and has certain odor. When cleaning, take the seafarer jacket, and connect the ventilation of the workshop! The cleaning agent is easy to glow, flammable and explosive, and do not smoke when using it!

Above is the relevant knowledge of two-component glue punch. I hope it will be helpful to you. If you need any other questions, please consult us at http://www.jntiannuo.com.

上一篇:自动打胶机不为人知的小功用!

下一篇:自动打胶机的调整与操作!