双组份打胶机出胶压力不足怎么办?

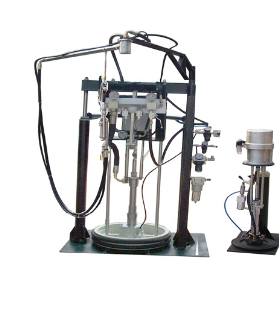

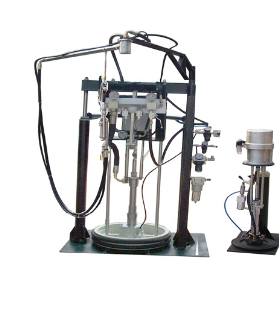

中空玻璃打胶机除了丁基胶涂布机以外,还有双组份打胶机,在使用较长时间和选择一般配置的情况下,会出现感觉手中打出来的压力不够,那么是什么原因导致的呢,我们应该如何解决呢?

In addition to butyl glue coating machine, there are two-component glue coating machine for hollow glass gluing machine. When using for a long time and choosing the general configuration, there will be a feeling that the pressure in the hand is not enough, so what causes it and how should we solve it?

混胶问题

First mixing problem

我们在混合的时候使用手工搅拌,直接暴露在空气中的搅拌混合的时候混进去的空气;

We use hand mixing when mixing, directly exposed to the air when mixing the air mixed;

第二 中空玻璃打胶机厂家生产问题

Production problems of the second insulating glass gluing machine manufacturer

双组份打胶机自动混合的,打胶机自动混合后有这样的情况那就是厂家生产的时候没有按照严格的工艺脱除A组份里面的空气原因造成的。

The two-component dispenser is automatically mixed. After the dispenser is automatically mixed, there is such a situation that the manufacturer did not remove the air in component A according to strict process during production.

那么应该如何解决这些问题呢?

So how to solve these problems?

1 液压站压力不稳,将混合芯轴清洗一下试试

The pressure of 1 hydraulic station is not stable, clean the mixed mandrel for a try

2 混合不均主要是U型管内部有胶凝固,需要定期清理。

2. The uneven mixing is mainly due to the rubber solidification inside the U-shaped pipe, which needs to be cleaned regularly.

3 机器共胶路网堵住了清洗一下

3. The road network of the machine is blocked and cleaned

上一篇:灌胶机的胶管应该如何更换?

下一篇:点胶机在密封胶中的应用!