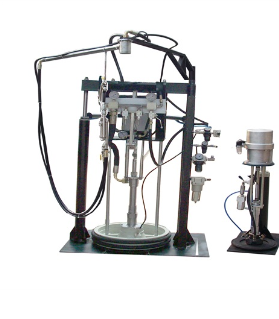

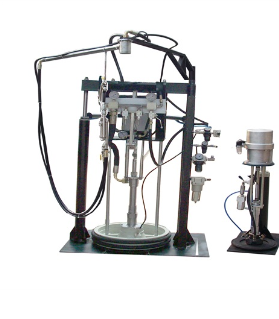

中空玻璃打胶机断胶解决方法!

中空玻璃打胶机断胶解决方法:

Solution to broken glue of hollow glass dispenser:

要进行 中空玻璃打胶机排除问题,然后针对性解决断胶的问题。

The first choice is to eliminate the problem of hollow glass gluing machine, and then solve the problem of glue breaking.

作为中空玻璃制作设备的 中空玻璃打胶机中丁基胶涂布机,在使用中会因为一点小问题影响使用,比如更常见的:

As a hollow glass production equipment, the butyl glue coating machine in the hollow glass gluing machine will affect the use due to a small problem, such as the most common:

中空玻璃打胶机为了增加制作效率调整是输送带速度很快,出胶量没法调整,导致断断续续的原因之一。

In order to increase the production efficiency, the adjustment of the first hollow glass gluing machine is one of the reasons that the speed of the conveyor belt is very fast, and the glue output cannot be adjusted, resulting in intermittent.

第二 对于胶缸和胶头的温度没有设置好,到时有的胶没有达到应有的温度,导致出现锯齿类的情况。

Second, the temperature of the rubber cylinder and the rubber head is not set properly, and some rubber fails to reach the proper temperature at that time, resulting in sawtooth.

第三 中空玻璃打胶机建议把温度调整到合适的温度,使丁基胶化掉,这样几乎不会出现以上问题。

The third insulating glass gluing machine suggested that the temperature should be adjusted to a suitable temperature to make butyl gel off, so that the above problems would hardly occur.

第四 如果是从中空玻璃打胶机刚开始使用到现在一直是这种情况 胶头出胶口有毛刺 胶头一般有两种 胶口处有槽和无槽两种

Fourth, if it's from the beginning of using the hollow glass dispenser to now, it's always the case that the rubber head has burr at the rubber outlet, and there are generally two types of rubber head: grooved and grooveless

第五 换胶以后出现这种情况 温度到达上限以后 出胶不正常 胶口处胶没有完全融化 手动排出一部分胶 也就是打几个框子 将压力调大 多打几个框子 将胶缸内的胶挤实。

After the fifth rubber change, when the temperature reaches the upper limit, the glue at the abnormal rubber outlet does not melt completely, and part of the glue is discharged manually, that is to say, several frames are set to adjust the pressure, mostly several frames are set to compact the glue in the rubber cylinder.

第六 双组份打胶机采购的丁基胶质量差,配置成本低,杂质堵塞引起的。

The quality of butyl rubber purchased by the sixth two-component beater is poor, the configuration cost is low, and the impurities are blocked.

第七 放胶后没有进行放气。

After the seventh dispensing, there was no bleeding.

上一篇:高速点胶机的产品特点以及使用方法!

下一篇:中空玻璃打胶机生产效率高不高?