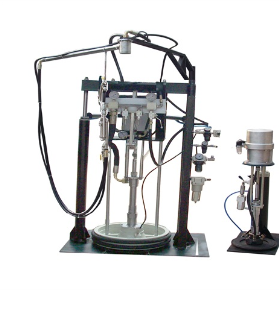

点胶机行业的发展思路!

我国网上配药机行业的发展历史并不长,从2005年到2007年,我国民营配药机企业开始崛起。一开始以代理为主,自主研发少。随着时间的推移,我们的设备的研究和开发水平的提高,网上调剂机也开始着手自主研发之路,但核心技术不成熟,产品由欧洲和美国仍是一个特定的产品水平距离四轴点胶机。

The development history of online dispensing machine industry in China is not long. From 2005 to 2007, private dispensing machine enterprises began to rise. At the beginning, the company focused on agency with less independent research and development. With the passage of time, the level of research and development of our equipment has improved, and the online dispenser has started to develop independently, but the core technology is not mature, and the product level from Europe and the United States is still a specific product level distance from the four-axis dispenser.

到目前为止,自动化的应用越来越多,越来越多的自动化厂家也开始涉足在线调色机行业,并逐步发展成为的调色机厂家,我们的调色机水平有了质的飞跃,完成了从手动调色到自动调色的转变。2009年底,据不完全统计,国内调色机生产厂家多达30多家,如果包括其他非自动化,国外调色机生产厂家多达几千家。数字是巨大的。

So far, the application of automation is more and more, more and more automation manufacturers begin to enter the online toner industry, and gradually develop into professional toner manufacturers. Our toner level has made a qualitative leap, and completed the transformation from manual toner to automatic toner. At the end of 2009, according to incomplete statistics, there were more than 30 domestic manufacturers of toner, and thousands of foreign manufacturers of toner, including other non professional automation. The numbers are huge.

当然,配药机行业的发展不会就此止步。自2011年起,政府加大力度,支持以点胶机和点胶机为首的一批电子制造设备。经过一轮产能的密集扩张,产能出现相对过剩后,随着群众条件和政策支持的逐步成熟,国产配胶机、配胶机的新一轮市场机遇孕育而生。造纸机行业产销量明显回升,供求关系也得到改善,行业业务能力稳步提升,甚经常出现“一机难求”的情况。

Of course, the development of dispensing machine industry will not stop here. Since 2011, the government has stepped up efforts to support a number of electronic manufacturing equipment led by dispensing machines and dispensing machines. After a round of intensive expansion of production capacity and relative overcapacity, with the gradual maturity of mass conditions and policy support, a new round of market opportunities for domestic dispensers and dispensers has emerged. The production and sales volume of the paper machine industry have obviously rebounded, the supply-demand relationship has also been improved, the business capacity of the industry has been steadily improved, and even the situation of "one machine is hard to find" often occurs.

目前我国点胶机行业的发展现状是:行业资源分散,中小企业多,规模小,综合实力不强;标准化程度不够高,不能满足客户定制需求;更重要的是自动点胶机工艺技术不高,虽然模仿技术已经很成熟,但是自主创新的水平还没有达到水平等等。配药行业的发展还存在许多不足之处,需要改进。

At present, the development status of dispensing machine industry in China is as follows: the industry resources are scattered, there are many small and medium-sized enterprises, the scale is small, and the comprehensive strength is not strong; the degree of standardization is not high enough to meet the customized needs of customers; the most important thing is that the technology of automatic dispensing machine is not high, although the imitation technology has been very mature, but the level of independent innovation has not reached the international level, etc. There are still many deficiencies in the development of dispensing industry, which need to be improved.

配药机行业应如何发展?

How should dispensing machine industry develop?

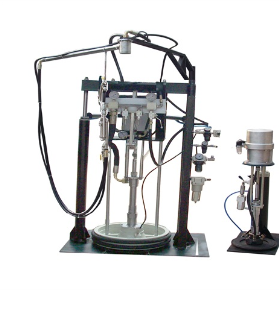

自动化:目前市场上已经出现了自动点胶机,其进一步的发展方向是使点胶更快、更容易操作!

Automation: at present, automatic dispensing machine has appeared in the market, and its further development direction is to make dispensing faster and easier to operate!

精度:主要针对配药的质量,配药不能溢位,不能太多,也不能太少,对于配药的量可以严格控制,达到非常准确的要求。

Accuracy: mainly for the quality of dispensing, dispensing can not overflow, not too much, not too little, the amount of dispensing can be strictly controlled to achieve very accurate requirements.

小型化:这要求配药机的结构更简单,更小。能够四处移动,不占空间,随时随地可用,是微型化的目标。

Miniaturization: This requires that the structure of dispensing machine is simpler and smaller. It is the goal of miniaturization to be able to move around, occupy no space and be available anytime and anywhere.

配药行业总体上应向自动化、标准化、精细化、智能化、微型化、产业化、抗恶劣环境、计量功能集约化发展。

In general, the pharmaceutical industry should develop towards automation, standardization, refinement, intelligence, miniaturization, industrialization, anti harsh environment, and intensive measurement function.

上一篇:如何使用点胶机做好点胶工作?

下一篇:自动锁螺丝机的操作规范!