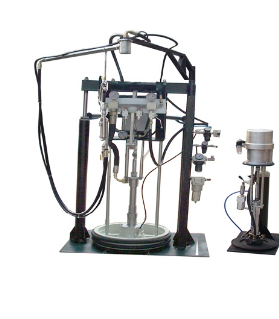

热熔自动胶点胶机的使用范围和特点!

热熔点胶机是工业加工中常用的点胶设备。它是一种自动滴胶工具,可将其加热,形成熔融状态,涂在固定胶上。热熔胶点胶机可以代替手工在各种平面或曲面物体上进行精确定位、画线甚是画线的操作,与手工操作相比,具有加工速度快、胶水更加均匀和提高加工效率的优点。下面由白青自动化来介绍热熔胶点胶机的主要适用范围和特点。

The hot melting point glue machine is a common dispensing equipment in industrial processing. It is an automatic glue dropping tool, which can be heated to form a molten state and applied on the fixed glue. Hot melt glue dispensing machine can replace the manual operation of precise positioning, drawing lines or even drawing lines on various plane or curved surface objects. Compared with the manual operation, it has the advantages of fast processing speed, more uniform glue and improved processing efficiency. The following is an introduction to the main application scope and features of the hot-melt glue dispenser by Baicheng automation.

一、热熔胶点胶机的功能和特点

I. functions and features of hot melt dispensing machine

多种热熔点胶机采用中英文液晶显示屏,可轻松实现点、线、画或不规则图形点胶操作,可实现任意三维非平面路径点胶。热熔胶点胶机完全支持阵列,图形浏览,3d,通用图形库插入和组编辑。超大容量文件存储系统,可同时保存多达99个调剂过程文件。胶量、配胶速度、配胶时间、停胶时间等可灵活设置。热熔胶点胶机配有特殊的点胶控制系统,可以稳定的达到胶量,破胶过程更加简单。自动恒温防固化系统,有效防止胶水在出口处凝固,堵塞针道。胶水可以预热,大大减少了更换胶水的时间。设有双工位、双工头配药功能,大大提高了工作效率。

A variety of hot melting point glue machine adopts Chinese and English liquid crystal display screen, which can easily realize the dispensing operation of point, line, drawing or irregular figure, and realize the dispensing of any three-dimensional non plane path. Hot melt dispensing machine fully supports array, graphics browsing, 3D, general graphics library insertion and group editing. Large capacity file storage system can save up to 99 reallocation process files at the same time. Glue quantity, glue speed, glue time and glue stop time can be set flexibly. Hot melt dispensing machine is equipped with a special dispensing control system, which can stably achieve the glue quantity, and the process of breaking glue is more simple. The automatic constant temperature anti curing system can effectively prevent the glue from solidifying at the outlet and blocking the needle channel. The glue can be preheated, greatly reducing the time for replacing the glue. Equipped with double station, double foreman dispensing function, greatly improving the working efficiency.

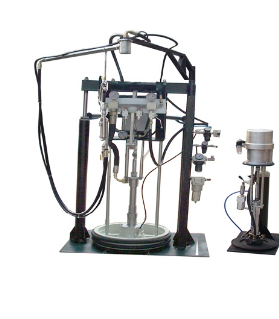

二、热熔点胶机使用范围

II. Application scope of hot melting point glue machine

方便使用热熔胶点胶机使用范围很广,一般适用于调剂使用更少的产品,更常见的使用产品,如手机屏幕外壳,小电子产品,导航器或汽车导航器,喇叭,笔记本,平板电脑外壳需要金属零件和塑料产品,如粘性的产品。热熔点胶机常用胶水有PUH胶、UV胶、导电胶、环氧树脂、速溶胶、红胶、银胶、锡胶等。

Easy to use hot melt glue dispenser has a wide range of applications, generally suitable for dispensing and using fewer products. The most common products, such as mobile phone screen shell, small electronic products, navigator or Car Navigator, speaker, notebook, tablet computer shell, need metal parts and plastic products, such as sticky products. Hot melting point glue machine commonly used glue PUH glue, UV glue, conductive glue, epoxy resin, fast sol, red glue, silver glue, tin glue, etc.

热熔胶点胶机的应用范围和功能的特点是把你介绍给他们,作为一种广泛的应用程序和功能和的产品,提供现代越来越多的电子设备处理,给与了很大的帮助手册分发不仅容易出错和低效率,现在许多工厂大多使用热熔胶胶配药操作。

The features of the application scope and functions of the hot melt glue dispenser are to introduce you to them. As a wide range of application programs and functions and comprehensive products, it provides more and more modern electronic equipment processing, and gives a lot of help to the manual distribution, which is not only easy to make mistakes and low efficiency. Now many factories mostly use the hot melt glue dispensing operation.

上一篇:知识和技术的创新是打胶机发展的重中之重!

下一篇:中空玻璃打胶机的耗电量怎么样?